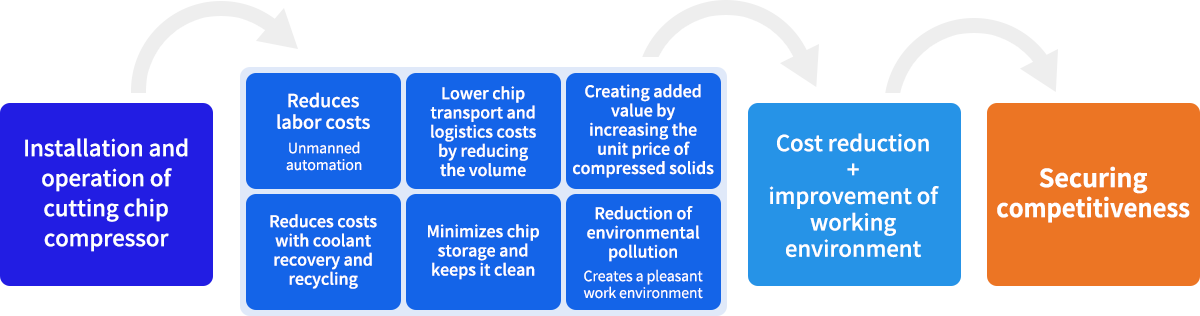

Effect of installation operation

The use of a chip crushing compressor eliminates the worry of waste materials.

-

01

COMPRESSIBILITY 1/50

Minimizes needle storage space by compressing and reducing cutting chips by up to 1/50.

-

02

RECOVERY RATE 95%

Recovers and reuses up to 95% of the cutting oil contained in cutting chips.

Reusable through filtration device (about 70% purification), cost-saving effect.

-

03

POWER EFFICIENCY 50%

50% power saving in average power efficiency including motor compared to other companies.

Standby mode during automatic operation is configured with an ultra-power-saving circuit, maximizing efficiency.

-

04

VALUE ADDED 30%

30% increase in added value of cutting chips

Increased unit price of compressed solids.Reduces logistics transportation costs by reducing volume.

-

05

LABOR COSTS DOWN

Labor cost savings

Unmanned automation

-

06

ECONOMIC ANALYSIS HIGH

Product competitiveness with reliable quality and performance

Minimization of cost and maximization of investment efficiency

The synergy effect of cutting chip compression

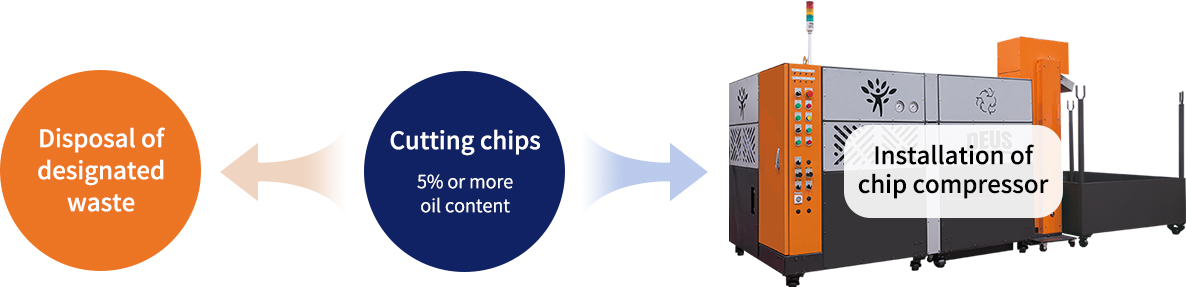

Laws related to cutting chip disposal (Reference)

If the oil content in the waste cutting oil and metal cutting chips (AL, scrap iron) generated at the workplace is more than 5%, it is classified as designated waste. (Article 3 of the Enforcement Decree of the Waste Management Act)